Mitsubishi Heavy Industries has now released more information on

its air carpet system for the new AIDA ships it is building for delivery in 2015

and 2016.

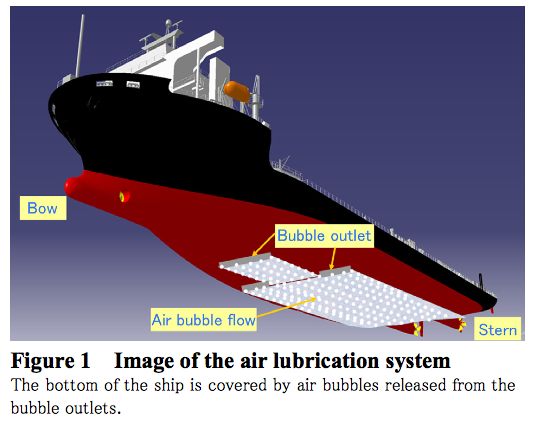

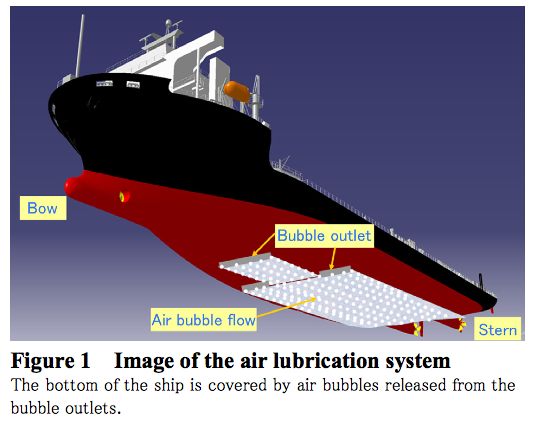

Mitsubishi Heavy Industries, Ltd. (MHI) will install its

innovative "Mitsubishi Air Lubrication System" (MALS) on two large cruise ships

to be built for the AIDA Cruises. MALS is MHI's proprietary technology that

reduces fuel consumption and carbon dioxide (CO2) by a layer of air bubbles

blown out from the vessel's bottom.

The application of the MALS for the two cruise ships ordered

by AIDA Cruises was decided in light of the customer's keen interest in lowering

fuel consumption and easing the burden on the environment. The system is

expected to reduce the vessel's fuel consumption by approximately 7%. The event

marks the world's first installation of MALS on a cruise ship. It is also a

significant milestone for the MALS as the cruise shipping industry requires

definite quality and performance on any devices so this first application in

this sector further demonstrates its reliability to the whole shipping industry.

MHI received the order for the two cruise ships in November 2011. The 125,000

gross tonnage (G/T), 3,250 passenger ships will be the largest ever constructed

for AIDA Cruises. Construction will take place at MHI's Nagasaki Shipyard &

Machinery Works, with deliveries scheduled for the spring of 2015 and 2016,

respectively.

The air blown out by the MALS from the vessel's bottom produces small air

bubbles which cover the vessel's bottom like an "air-carpet", which reduces

friction between the hull and seawater during navigation. For the MALS, MHI uses

special in-house developed high-efficiency blowers and state-of-the-art fluid

simulation analysis tools to configure the arrangement of air outlet points to

achieve maximum friction reduction at optimized air-blow volume. With these

advanced innovations, MHI expects a 7% energy-saving effect. In 2010, MHI has

already verified the performance of the MALS with an approximately 13% fuel

consumption reduction during extensive sea trials on two module carriers which

was the first commercial application of the MALS for the vessel in operation.

Following the successful launching of the MALS on module carriers, MHI has

completed a newly developed concept design for bulk carriers, a major marine

transportation vessel, that enables an approximately 25% reduction in CO2

emissions compared to conventional vessels, thanks to application of the MALS

complemented with high-efficiency hull form and improved propulsion system. MHI

will provide its conceptual design of this energy-saving bulk carrier for three

grain carriers to be built for Archer Daniels Midland Company (ADM), a major

U.S. grain handler.

Given the current trend toward adoption of international marine transportation

rules for reducing environmental burdens, coupled with continuing fuel price

escalation, demand for more energy-efficient vessels is steadily increasing. In

response, MHI aims not only to further strengthen its marketing activities for

new MALS-installed ships such as module carriers, bulk carriers and cruise

ships; it also intends to promote business in retrofitting MALS to existing

vessels. Simultaneously, the company will conduct focused marketing activities

for its environment and energy-saving related technologies, including licensing

of MALS technologies, and also build up its engineering business through

provision of eco-ship related technologies and increased sales of energy-saving

systems. |

|

|

|

Worldwide Travel & Cruise Assoc., Inc.

150 S. University Dr. Ste E,

Plantation, FL 33324 - USA

Tel: +1 954 452 8800 Fax: +1 954

252 3945

EMail:

sales@cruiseco.com |